Muhammad Hashmi

Member-

Posts

122 -

Joined

-

Last visited

-

Days Won

8

Content Type

Profiles

Forums

Events

Everything posted by Muhammad Hashmi

-

Dear Members Struggling with a very hard time these days. Anybody have relations in good reputable engineering consultancy for the job of senior structural engineer in Saudi Arabia or any part of gulf region please post. I will share my resume. My resident permit ( IQAMA) is transferable and notice period is 2 months , in case vacancy in Saudi Arabia. Currently located in Jeddah, but happy to relocate.

-

Engineering Education Vs Engineering Practice!!!

Muhammad Hashmi replied to Waqar Saleem's topic in Shout Box

agreed -

Minimum Reinforcement in Column!!!

Muhammad Hashmi replied to Waqar Saleem's topic in Concrete Design

Yes. We can 10.3.1.2 For columns with cross sections larger than required by considerations of loading, it shall be permitted to base gross area considered, required reinforcement, and design strength on a reduced effective area, not less than one-half the total area. but need to be considered the following as well This provision shall not apply to columns in special moment frames or columns not part of the seismic-force-resisting system required to be designed in accordance with Chapter 18. -

Assalam O Alykum In the same project / same consultant engineer 1. For G+1 story building having length 45m and width of 16m emphasizing to use the structural lean / blinding concrete ( non reinforced with fiber or mesh) having thickness 200mm and 200mm offsets minimum from all sides from the footing with compressive strength 30MPA. 2. Provide the size of footing by considering the bearing capacity of blinding / lean concrete 300 Kn per meter square or 30 MPA. In other words, footings will be designed based on the compressive strength of concrete. 3 Provide the size of blinding offsets from the face of footing by considering the bearing capacity of soil that is 200 Kn per meter square. Does any code allow us to use such type of practice to get economical result. My practice is to provide blinding just to have plain surface /level or safe from mud at the time of raining. If seniors can help particularly in this regard

-

Tension force @ top of retaining wall

Muhammad Hashmi replied to Muhammad Hashmi's topic in Concrete Design

Assalam O Alykum What he is saying is "Concrete is stronger in compression then in tension" In case found any tension on the walls of the tank while analysis put the full minimum horizontal reinforcement on the tank walls where tension develops 0.002bxh. May be I am not explaining well? -

Assalam O Alykum In one of our under construction project. We have one Under ground water tank subjected to truck loading AASHTO HS20. Water tank size is 45x11mx3.0m clear height. 1. The tank walls are probed from the slab at the top & fixed at the bottom. 2. The tank walls are also checked based on water pressure and no backfilling around at the time of leak test. 3. Consultant engineer made some comments and on of his comments is show below " The code requires to put the full minimum horizontal reinforcement on the sides where tension develops so if the tension develops on both sides considering all loading case , then both sides must receive full minimum reinforcement each side" My question is that when the retaining wall is braced by means of slab on the top, How the tension force will develop. second in case at the time of leak test. How do we calculate the tension force at the top of wall. If anybody can help in this regard?

-

Assalam O Alykum In one of our project ( Hospital building) we have Rcc walls are proposing instead of lead shield ( Radiation area for cancer patients). Rcc walls proposed thickness by the radiation consultant varies from 160mm to 240mm. Rcc walls are none load bearing, floor to floor height is 4.2m. However, Non-load bearing Rcc walls height is 3.1m I want to know is there any code criteria that for such thickness we must have 2 layers of vertical reinforcement and up to that thickness yes we can put 1 layer. Can you please help in this regard.

-

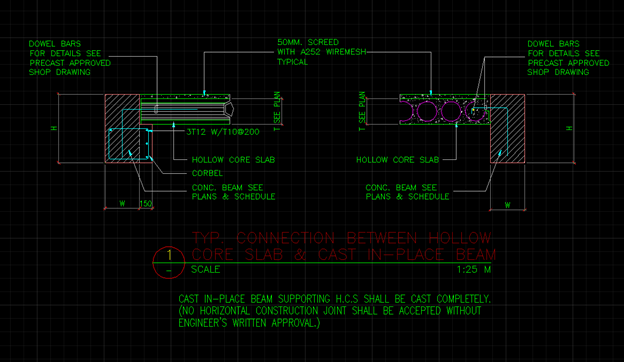

Assalam O Alykum Dear Badar Do you have any authentic ledge design spread sheet for the cast in place ledge for L and T ledges both. Small confusion regarding the torsion on cast in place T Beams. If we are talking about torsion on the T-beam or the middle beams where the Hollow core slab is resting on both sides. We are saying that torsion occurs during construction right?

-

Hi Abbas The special GPR (Ground penetration Radar test) looks suitable for your case that is generally applied to check the workability of concrete joint , honey comb , cold joint or weak concrete , change in properties of material. Voids and cracks by using electromagnetic radiation for that type of structure.

-

Assalam O Alykum You are right we can go with the carbon fiber for slab strengthening. But due to management issue and working in a contracting company cannot go for that.

-

Assalam o Alykum Can anybody advise?

-

Assalam O Alykum In one of our constructed project, the architect proposed hydrotherapy water pool on one area of existing flat slab of thickness 350mm. ( Hospital building) After analysis it is observed that the area with in the proposed location of pool required slab strengthening. There is absolutely no chance to add steel columns or concrete columns underneath. The steel beams can be proposed underneath, but I am trying to avoid due to rusting and corrosion due to any leakage of water at later stage. My questions are ; 1. How to calculate number of shear connectors , diameter of shear connectors and spacing between the shear connectors to work both existing flat slab thickness 350mm and proposed flat slab thickness varies between 75mm to 100mm monolithically and to avoid any chances of horizontal shear. 2. The requirement of reinforcement is coming at the bottom, where do I put these bars at the middle ? or above the concrete cover. I am also attaching the sketch for better understanding. If anybody can help in this regard. Shear connectors Flat slab.pdf

-

Assalam O Alykum Do you understand that the supporting beam is subjected to torsion, in addition to shear and bending moment, due to connection detail chosen for transferring forces from the precast hollow-core slab to RC beam? yes i understand. Final connection detail is not yet received from the designer of HCS. The detail which I shared is preliminary. Can you imagine what will happen if beam has not been designed for the interaction of torsion and shear? Can you imagine that the beam will tend to twist or rotate about its longitudinal axis if the adequate amount of torsional reinforcement is not present? What will be the result of that rotation? Yes I can understand. In this case, can it lead to an increase in connection forces that may not have been accounted for? Any possibility of sending any recommended connection details to avoid any torsion or reduced the torsion on the cast insitu beams.

-

Assalam O Alykum Can anybody help in giving reference for the allowable settlement values of piles itself? I am unable to find it out but have something like a thumb rule that it is 2% of dia of pile.

-

Make changes if you are redistricted in the choice of section size for beam. In this case, how will you know if the additional flexural demands in hollow-core panels, due to torsion-related cracking in RC beam, will be taken into account? Eng Badar I could not get this point

-

No doubt about that Badar is super structural engineer. Wish can get a chance to work with him.

-

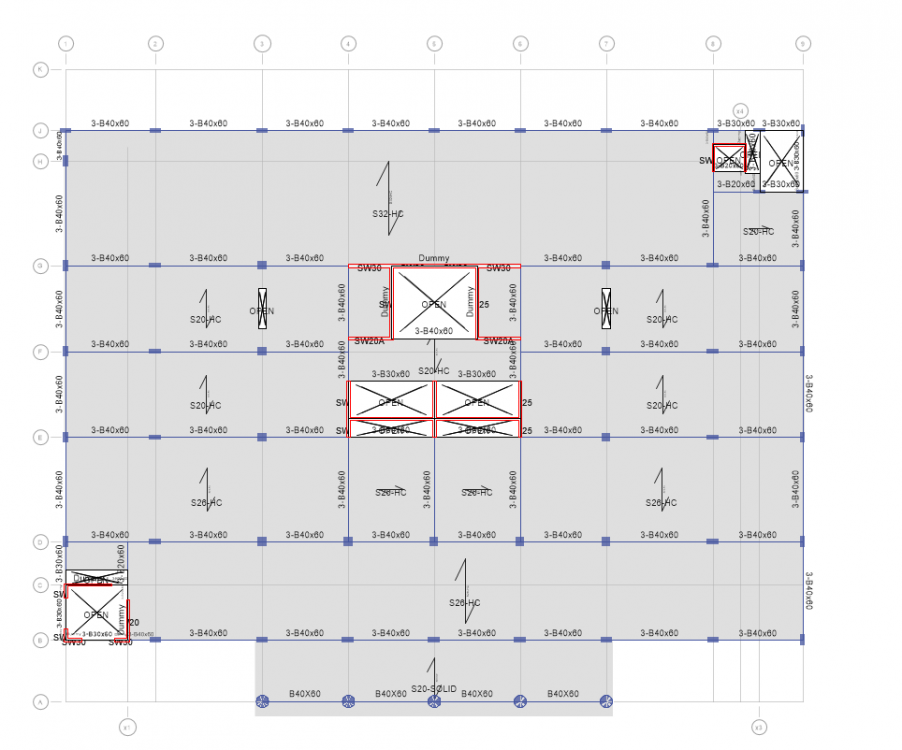

Thanks Badar Framing plan is attached for one floor almost same for other floors as well. How much will be the torsional constant shall I consider to design the beams.

-

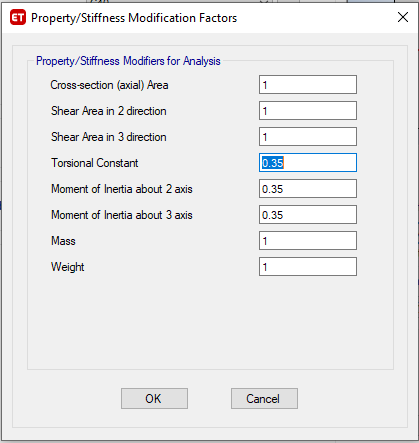

Thank you Badar for your continuous support. You are right I am unable to realize How much will be the torsional constant shall I consider design the beams. apologies if you advice about the below as well Diaphragm I applied as a semi rigid. Building components such as columns , shear walls will be designed based on the membrane as well or can say shell with stiffness modifier 0.01? shall I say like that

-

Thank you Muhammad for clarification 1. You mean linear load plus torsion on the beam will be the effect on the cast in place beams. Shall I understand torsional constant must be applied on the program along with stiffness modifiers of beams 0.35? 3. Diaphragm I applied as a semi rigid. 4. Building components such as columns , shear walls will be designed based on the membrane as well or can say shell with stiffness modifier 0.01? shall I say like that

-

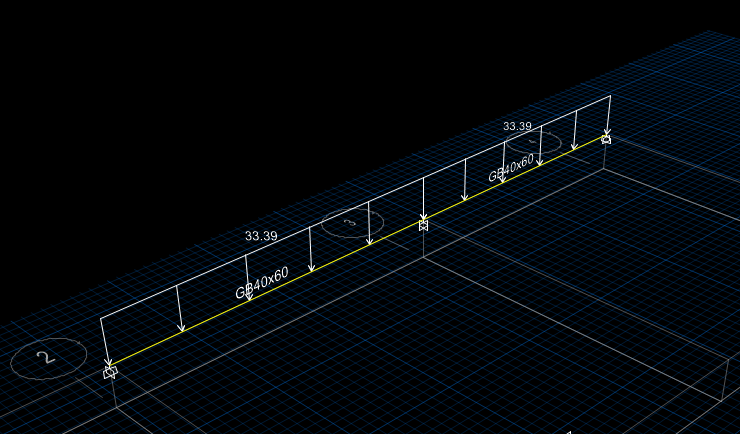

Thanks Muhammad What if I can define slab as a shell and reduced the bending M11 direction , bending M22 direction and bending M12 direction = 0.01. Or apply the linear load on the beam in the direction of one way slab or in other words as per the below snap shot

-

Thanks Muhammad for your reply Dowel bar will be provided to make it as connection between the hollow core slab and cast in place beams. Beams supporting the hollow core slabs will be designed by us and hollow core slabs will be designed by the specialists. My question is that this dowel bar will really create a composite action between hollow core slabs and cast in place beams & considered enough to define the slab as shell in our E-tabs model. To design the slab as membrane will increase the amount of reinforcement too much.

-

Assalam O Alykum Small question The hollow core slabs are defined as a membrane or shell element ( In the direction of hollow core panels) As a hollow core slabs are rests by bearing on the beams with grout and screed on the top with no composite action between beams and hollow core slab. Thank you

-

CORE CUTTING ON EXISTING SLABS

Muhammad Hashmi replied to Muhammad Hashmi's topic in Concrete Design

Assalam o Alykum all Dear Eng. Badar Can you help in marking as a circle on case a to case d on the attached drawing? For the said issue. Due to location of modification in the architecture and client requirement sleeves that are circled in Yellow and red color are the once that required core cuts on the existing flat slab. Yellow are 75mm and Red are 150mm. Unwanted sleeves filled with non shrinkage high strength grout right ? Any other advise while doing these core cuts on site will be helpful. Thank you R0_S-405-3F-A-MUR-4.dwg -

Assalam O Alykum In one of our under construction project we are using hollow block work walls. My question is at the location of fixtures toilet or kitchen ( Wet areas) means WC and Wash basin, Solid block work wall is better or Filled the layer with M20 concrete as the hollow block work will surely get crack after some time. Thank you