Dik

Member-

Posts

45 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Events

Everything posted by Dik

-

What is a UGWT? UnderGround Water Tank? Best to locate it as far from the foundations as possible and as close to the floor. If you have frost issues, there are a couple of other issues. what type of foundations do you have?

-

I assume your mix design is 90 MPa concrete (@28 days). I don't know what the concrete object that has the cracking is. For that strength gain, there is likely a very small portion of fly-ash, so there is likely a lot of cement powder. What is the size of your aggregate; you could have a lot of shrinkage. 1.5% air is not unusual. You can have that amount with normal mixing. This is normally less than 1%. In our environs exterior concrete usually has about 6% or 7% for frost resistance. A lot of our concrete has fly-ash for economy. I've not used self compacting concrete, but have often spec'd superplasticisers. I always spec mechanical vibration, even for piles and caissons. Dik

-

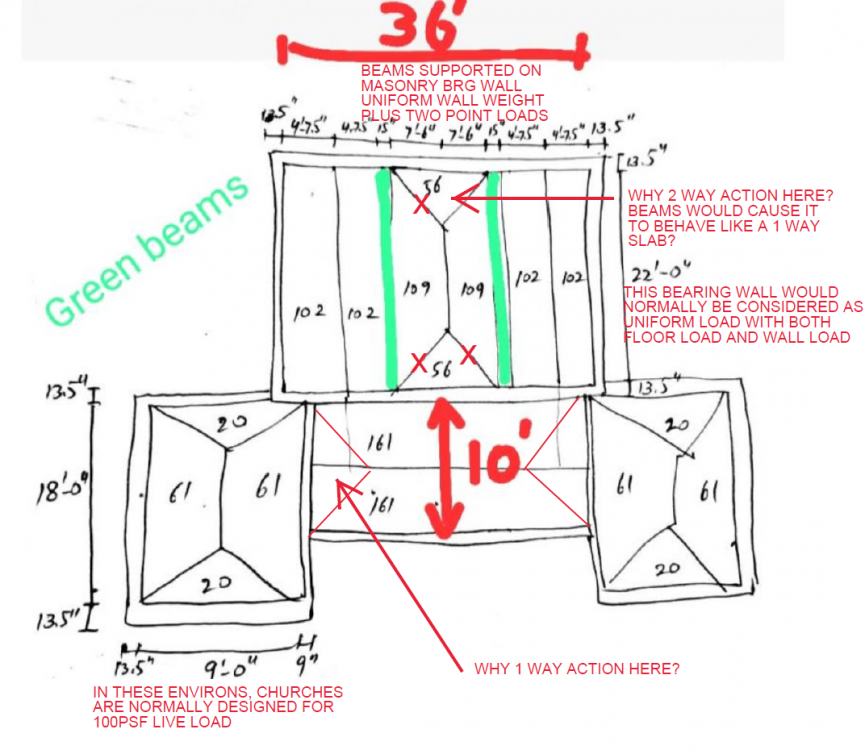

Just because the aspect ratio of the slab is greater than 2 or whatever, the flexibility of the beams, as opposed to it being a wall support would tend to cause it to behave as a one way slab. Even your load takedown for the wall, as 2 point loads from the slab indicates the one way action. Same with the verandah, it doesn't matter what the use of the slab is, it would tend to distribute some of the load at the ends to the adjacent masonry wall. The aspect ratio is still pretty small.

-

Thanks for the added information. For personal reasons, I don't want to review your calculations, but it looks like you have things in order...

-

In these environs, only if a building is unheated (eg. some warehouses, parkades, etc.) nearly all buildings are heated in the winter and cooled in the summer. Thermal change in dimensions is normally accommodated by construction details at the time of construction. Once a building is enclosed, there is very little thermal movement.

-

-

Lots of questions... I cannot tell what the framing for this is. Are the floors structural concrete? or something else. What is the roof construction? Is it one way, or two way spanning for the slab? If slabs, is the span for the upper part in a left-right direction? Why is the middle panel in the upper part different than the panels at each edge? Wouldn't they all be the same? It looks like the spans are approx 15'; does that mean that you are using a 6" slab or something similar? I don't know what your numbers 61, 61, and 20 represent. I don't know what your loads 50 + 50psf mean.

-

Do you have special finishes? 50psf superimposed load is quite high... this is normally less than 10psf. Is it treated as DL or LL, for reduction purposes? The load is accumulative if you have several stories.

-

Can Any provide guidance on designing a 14-story building in Etabs using flat slabs with a thickness of 30 cm? What checks are necessary for flat plate slab buildings? Also, how can I check the punching shear of slabs at column locations? If you have a re

Dik replied to Zeeshan Ilyas's topic in Seismic Design

Some questions... What is the slab span? Is it a seismic area? Can you use a thinner slab with drop panels?- 1 reply

-

- flateplateslab

- etabs

-

(and 6 more)

Tagged with:

-

What foundation is most suitable for a house close to the sea?

Dik replied to symakhan's topic in Concrete Design

If subject to salt water, 4ksi concrete is likely at the lower edge for corrosion resistance. Concrete cover to reinforcing is also very important and should be in the order of a couple of inches, and more, depending on the environment. You also want to minimise slump to get a good dense concrete. -

Pour strips work OK, but generally not when you have a transition in structures. The plan is a compilation of several structures. You want a real joint at those junctures.

-

If you have abrupt changes in the building envelope, pour strips are of little use.

-

I use Bricscad in lieu of Autocad. I don't have the current edition. I'm not a CAD operator and only produce *.dwg files occasionally. You can still get perpetual licenses for Bricscad and it is a fraction of the cost of AutoCAD. When I purchased my copy, it was less costly than AutoCAD LT and worked as well as the full AutoCAD. It is about 99.9% compatible. I've opened 80meg 3D drawings that were originally done in AutoCAD, and edited them and there was no trouble for a CAD operator to open the edited files. I'm also a member of the AISC and Steel Tube Institute. Both these organisations have excellent reference material.

-

What is the construction of the fort? Is it stone or 'baked bricks'? With the latter, you have to be careful that the mortar strength does not exceed the brick strength (actually both, but mortar being stronger than brick is more common). You want any failure of the wall to occur in the mortar joint and not through the brick. It's common to see failure of historic brick because they have used a Portland cement mortar. Historic_Brickwork_21-07-05.pdf

-

What foundation is most suitable for a house close to the sea?

Dik replied to symakhan's topic in Concrete Design

If coastal and a small project, then find out from others what type of foundation is generally used in the area. It depends on the soil type and bearing strength. If subject to salt water, corrosion will be an issue and you want to have a dense concrete, adequate concrete cover and adequate strength. You might consider HDG reinforcing steel for added corrosion protection. With climate change coming up, you also want to be high enough for the water level to rise several feet without it affecting the building. Dik -

Thanks... the building is extremely irregular... I don't think you can travel 150' without 'hitting' an irregularity. I was trying to find a source for control joints based on the irregular building envelope.

-

I don't know if this will post... the sketch is public domain... The red lines are joints that I've suggested. Due to the difference in elevation of the varioius components, there could be others.

-

Thanks for the response... I do not have release to provide the plan. The building consists of three or four smaller structures (still regular sized buildings) and the 'footprint' of the structure is extremely irregular. The smaller sized structures are of different heights (multi storey). It is a hotel complex in Vietnam. Construction is reinforced concrete slab with drop panels, and in my opinion, needs real construction joints. The engineer that was looking into the design was intending on using expansion joints predicated on maximum distance recommended by ACI. In reality the building should have joints at the interface of the various buildings. He was looking at a couple of joints as opposed to maybe 8 or 10. I was wondering if somenone had a reference to joints based on building envelope issues. Again, thanks...

-

I'm an old codger with over 50 years of good engineering experience. I'm still actively designing. Most of my work, now is related to structural steel connections, but my experience is very wide. The reason for joining this site, is that there is an engineer in Vietnam that has a very irregular building 'footprint' (shape) and is seeking advice for locating expansion (control) joints. The joints are not constrained by dimension, but are determined by the irregularity. Thanks. Dik