-

Posts

578 -

Joined

-

Last visited

-

Days Won

138

Content Type

Profiles

Forums

Events

Everything posted by Ayesha

-

Your story stiffness is independent of the type of load as long as we are talking about the elastic response (Linear Static). You can use the same story stiffness or calculate yourself manually for each story by applying a 1kips load and then finding out the corresponding deflection and diving 1kip by that deflection,. I don't know why the software isn't showing you. Maybe you aren't doing a linear time history analysis. I am just guessing.

- 2 replies

-

- stroy stiffness

- etabs

-

(and 1 more)

Tagged with:

-

You will need to get familiar with Terzaghi and his factors. Start by determining the internal friction angle of the soil. This can be assumed or determined analytically by testing the soil. Based on the angle of internal friction you can determine the bearing capacity factors for general shear denoted as N.c N.q and N.y (y=gamma). The general equation for ultimate bearing capacity for shallow continuous footings is given as: q.ult = 0.5*(gamma)*B*N.y + c*N.c + (p.q + y*D.f)*N.q Where: B = width of the footing c = cohesion of soil p.q = surcharge pressure D.f = depth of the footing Once the ultimate bearing capacity has been determined, find the net bearing capacity by subtracting out the overburden, typically given as y*D.f. This is the net pressure the soil can support beyond the pressure applied by the existing overburden. Now simply divide by your factor of safety (3 is typical, but can be as high as 6) and viola, you now know your allowable bearing capacity. *If you are interested in this information for any heavy civil projects, you should consult a geotechnical engineer who will give you the actual allowable bearing capacity of your specific soils on site. Structures should not be designed without having actual tests performed on the soil. The above information is provided for academic purposes. Use the information above and calculate the bearing pressure yourself.

-

You should create a new topic instead of posting in a totally irrelevant topic. To answer your question, go for deep foundations like piles.

-

Did you model the masonry using Shell elements?

-

Girts and Purlins affect of Column Beam Effective Length

Ayesha replied to Salma Jabeen's topic in Steel Design

I am not sure what the reference is but this formula should be for a member being used as column, not as beam. Beam would never have significant axial load (generally speaking) so why use this formula? -

This topic has been extensively discussed in the forum. See the topic below.

-

So you are worried about that if the supporting slab under the transfer column would fail in shear? Did I read your question right?

- 6 replies

-

- transfer girder

- bursting effect

-

(and 2 more)

Tagged with:

-

Girts and Purlins affect of Column Beam Effective Length

Ayesha replied to Salma Jabeen's topic in Steel Design

@Ahmed1, where you say minor axis compression capacity, do you mean minor axis flexural capacity for compression flange? -

There are detailing requirements for seismic that require you do a 180 degree tie as they don't open up during earthquake- usually done for stirrups and ties. The requirement varies from code to code based on seismic classification. Standard 90 degree hooks are generally provided for longitudinal bars. Now, with regards to your questions. The drawing should clearly state where it is A or where it is G. There are different lengths because the diameter of the bar around which the bar that is being turned could change this length.My guess.

-

You need to fix your Frame Output Stations http://docs.csiamerica.com/help-files/etabs/Menus/Assign/Frame/Frame_Output_Stations.htm

-

You need to upgrade your computer or try removing the background tasks to free up memory.

-

Underground water tank base slab as a foundation

Ayesha replied to Fatima Khalid's topic in Foundation Design

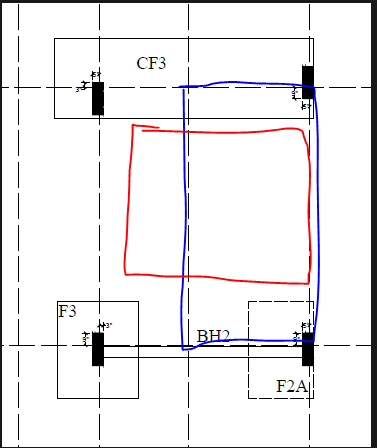

Walikum asalam, Yes you are right. 30" thickness is way too much for a house. What is the load on your exterior column. Is there a wall too between the columns? Other options include moving the water tank to avoid building columns. See image below. -

That is very smart.

-

I think he wants to know which service combos? Earthquake wind etc

- 11 replies

-

- safe raft modeling

- soil pressure

-

(and 1 more)

Tagged with:

-

Here is an example to explain what I mean by general values: If you have a shear wall located on a raft foundation and the only area where you have high stresses is under the shear wall, and the rest of raft has values within the acceptable range, then ignore the high values right under shear wall and focus on more general values or focus on the rest of the foundation. For your case, @Hafsa Azmat has correctly pointed out that averaging wouldn't work or it would be very limited. For example you can average 11 and 10 E3 zones (The purple colored stresses) as that is more of a concentrated zone. Not all of the raft. Hope that helps.

-

You should not use LRFD combinations for checking bearing capacity. Use service load combos only for bearing capacity and LRFD for moment and shear design.

- 11 replies

-

- safe raft modeling

- soil pressure

-

(and 1 more)

Tagged with:

-

Here is a suggestion. You can work on a method to evaluate stiffness contribution of in-fill masonry walls in moment frames.

-

As far as high-rise design goes, there is always areas of high concentration in a raft. General practice is to ignore them and focus on more general values and see if they are within the allowable limit or not. There is no guideline for stress average. People do it by using their engineering judgement.

-

You should keep things simple. Just use rectangular section as it is more conservative.

-

You can provide steel for bending if they are significant. In order to finalize design, you need to do two things. Understand your shell local axis and how forces are reported in SAP2000/ ETABS. See topics below.

-

You are right. This has been changed probably. You can try Assign> Area > Area Thickness Overwrites (Shell). See attached snapshot.

- 5 replies

-

- shell element

- insertion point

-

(and 1 more)

Tagged with:

-

Say you are retrofitting a beam to increase its depth from 12" to 18". You can model and 18" beam in ETABs and then manually design the retrofit based on new analysis forces. That is what I have been doing. Say you are using dowels or shear studs to connect the old and new beam. So you need to check that the dowels are developed and able to transfer the required force.

-

See the following topic.

-

Its providing your reinforcement as % of cross section (0.0064 is 0.64%*AG). For example for you need to divide this reinforcement for both wall faces. For shear, you need to provide 0.84 in^2/ft reinforcement / vertical foot on both faces.